Lewter District Class A Office

Size of Project

75,000 SF

Number of Floors

5

Location

Huntsville, Alabama

Owner

Emergent Properties

Industry

Commercial Real Estate / Office

Type

New Construction

Status

Delivering Q1 2026

Architect

EskewDumezRipple

Overview

A New Anchor for Downtown Huntsville

223 Washington Street—also known as the Lewter District Class A Office—was conceived as more than a single building. It was envisioned as a catalyst for downtown Huntsville, setting a new benchmark for what dense, walkable, mixed-use development could look like in a historic urban core. Developed by Emergent Properties, the five-story project blends ground-level retail with four floors of modern Class A office space, placing businesses in the center of a vibrant district surrounded by restaurants, shops, and entertainment—all within walking distance.

For the development team, the goal was clear: deliver a world-class office building that could compete in any major market while respecting the scale and character of downtown Huntsville. The project needed to move fast, perform financially, and prove that cities don’t have to sprawl outward to grow. That ambition set the tone for everything that followed.

Building “In a Box”

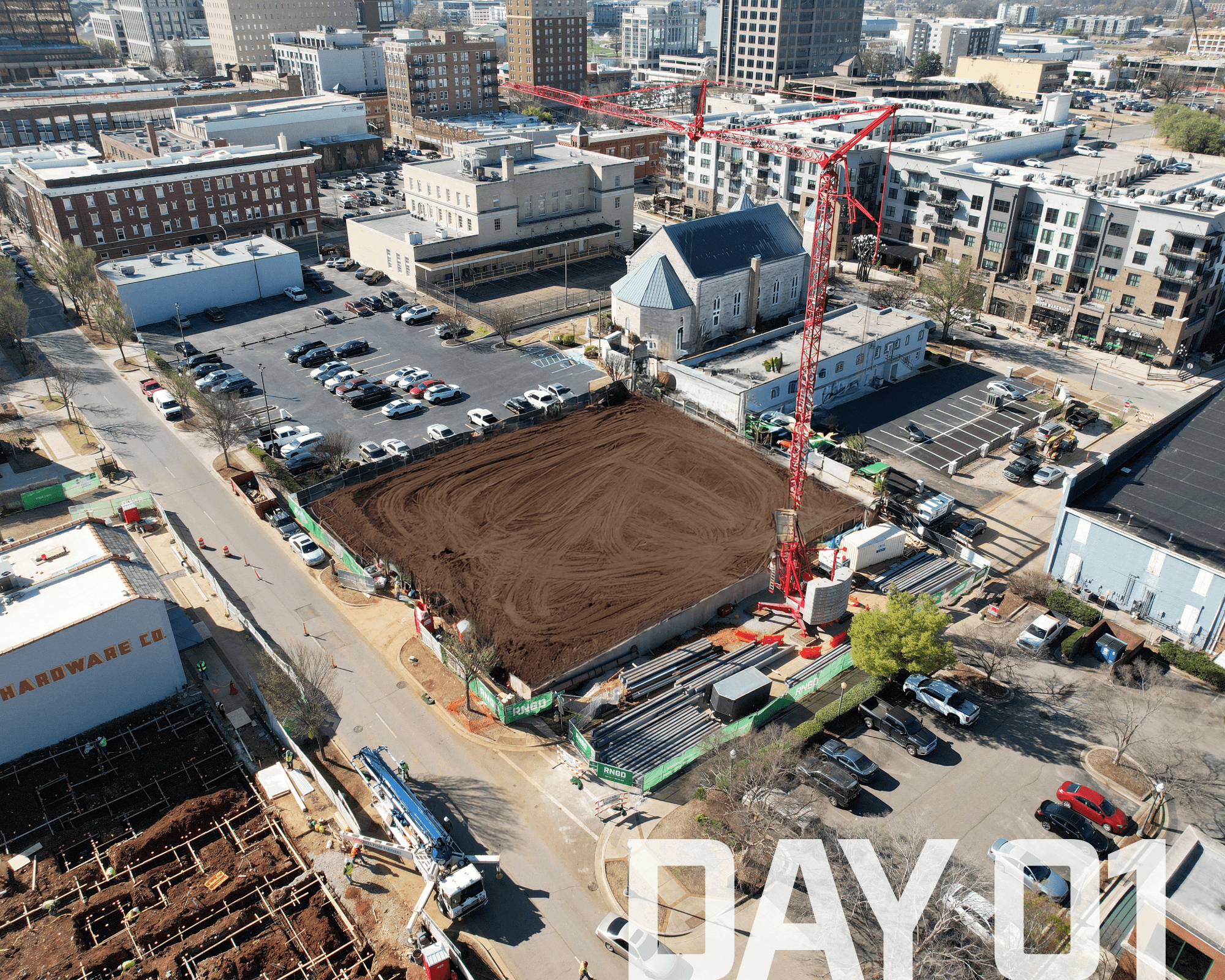

From the moment RNGD walked the site, the challenge was obvious. The building footprint stretched property line to property line, leaving virtually no room for staging, storage, or inefficiency. Every delivery, every lift, and every crew movement had to be planned with precision. In total, more than 400 tons of structural steel and 196 exterior wall panels would need to arrive, install, and move off the site without disruption.

Adding pressure, the project launched in a tough macroeconomic environment for new office construction. Cost certainty and schedule control weren’t nice-to-haves—they were essential. Traditional construction methods left too much risk on the table. To meet the moment, RNGD proposed a fundamental shift: move the building’s upper levels to a prefabricated system that integrated structure and envelope into a single coordinated solution.

Early Design Alignment and Integrated Execution

Once the project committed to a prefabricated exterior system, early integration became non-negotiable. RNGD worked closely with EskewDumezRipple to protect design intent while translating architectural vision into a buildable, manufactured solution. That collaboration started early, aligning geometry, façade articulation, and connection logic before details were locked.

Internally, RNGD’s steel, BIM/VDC, and prefabrication teams worked as a single unit. Structural steel was designed not just to support the building, but to act as the precise mounting system for the exterior panels. Through coordinated modeling and design-for-manufacturing workflows, the team verified tolerances, embed locations, and panel interfaces down to the eighth of an inch.

By resolving these conditions digitally and collaboratively, the team eliminated downstream rework and ensured the building could move seamlessly from design to fabrication to field installation.

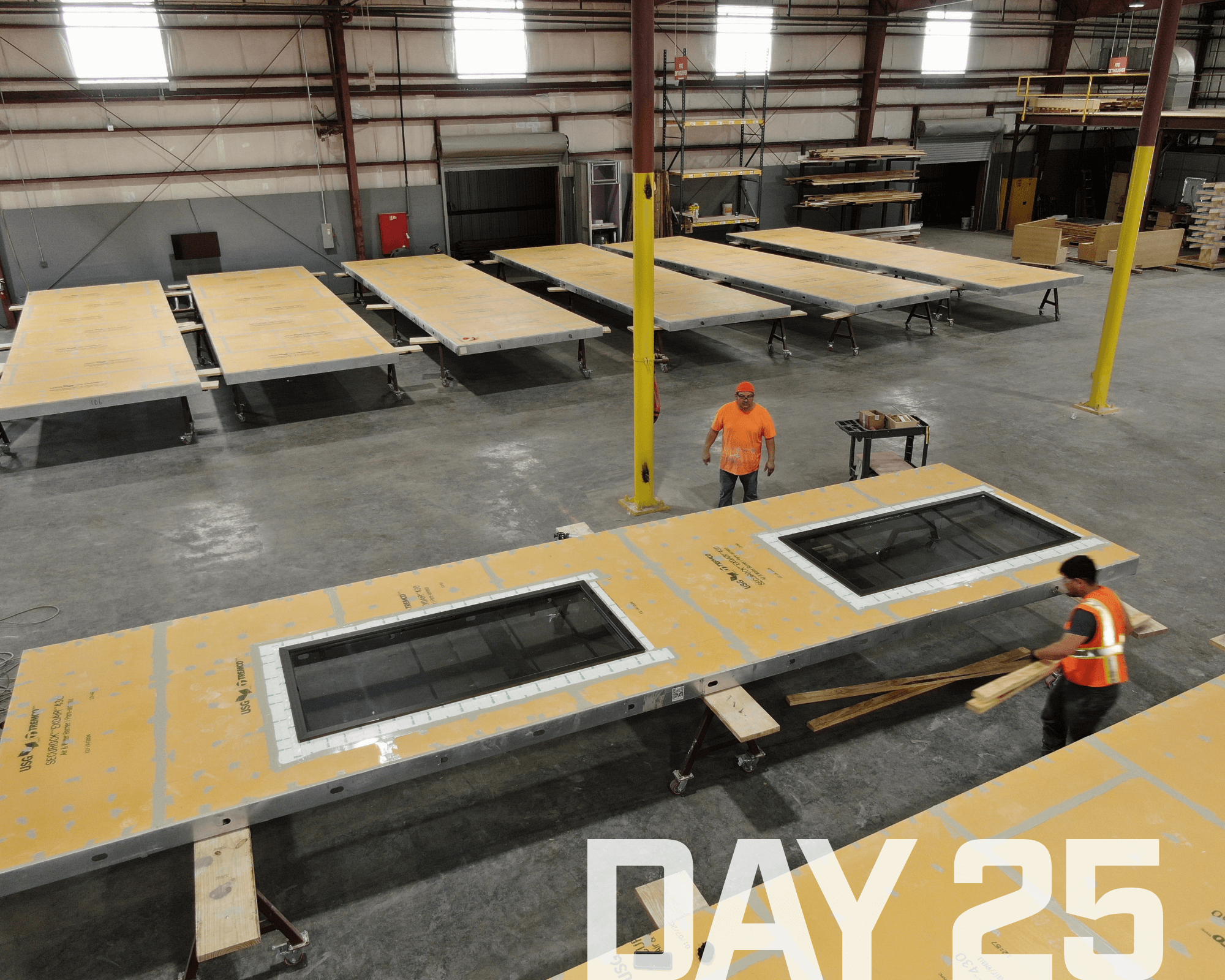

Manufacturing the Envelope, Then Installing With Precision

With design fully coordinated, it was now time to develop to panels. All 196 exterior wall panels were manufactured in RNGD’s prefabrication facility and were built as a complete assembly—integrating framing, waterproofing, structural attachment points, and exterior finishes—allowing quality, safety, and production flow to be tightly managed before anything reached the jobsite.

To bring manufacturing discipline to the process, each panel was assigned a QR code tied to inspections, production tracking, and quality control data. As panels moved through framing, waterproofing, and final inspection, foremen and superintendents logged progress in real time. This visibility allowed the team to identify bottlenecks, address deficiencies early, and continuously improve production while fabrication was still underway.

Once complete, panels were sequenced, loaded, and shipped to Huntsville in exact installation order. On-site, the field team used the same QR system to confirm panel placement and installation sequence, ensuring a smooth, uninterrupted erection process. The result was a data-driven prefab workflow that delivered speed, consistency, and repeatable quality on a constrained urban site.

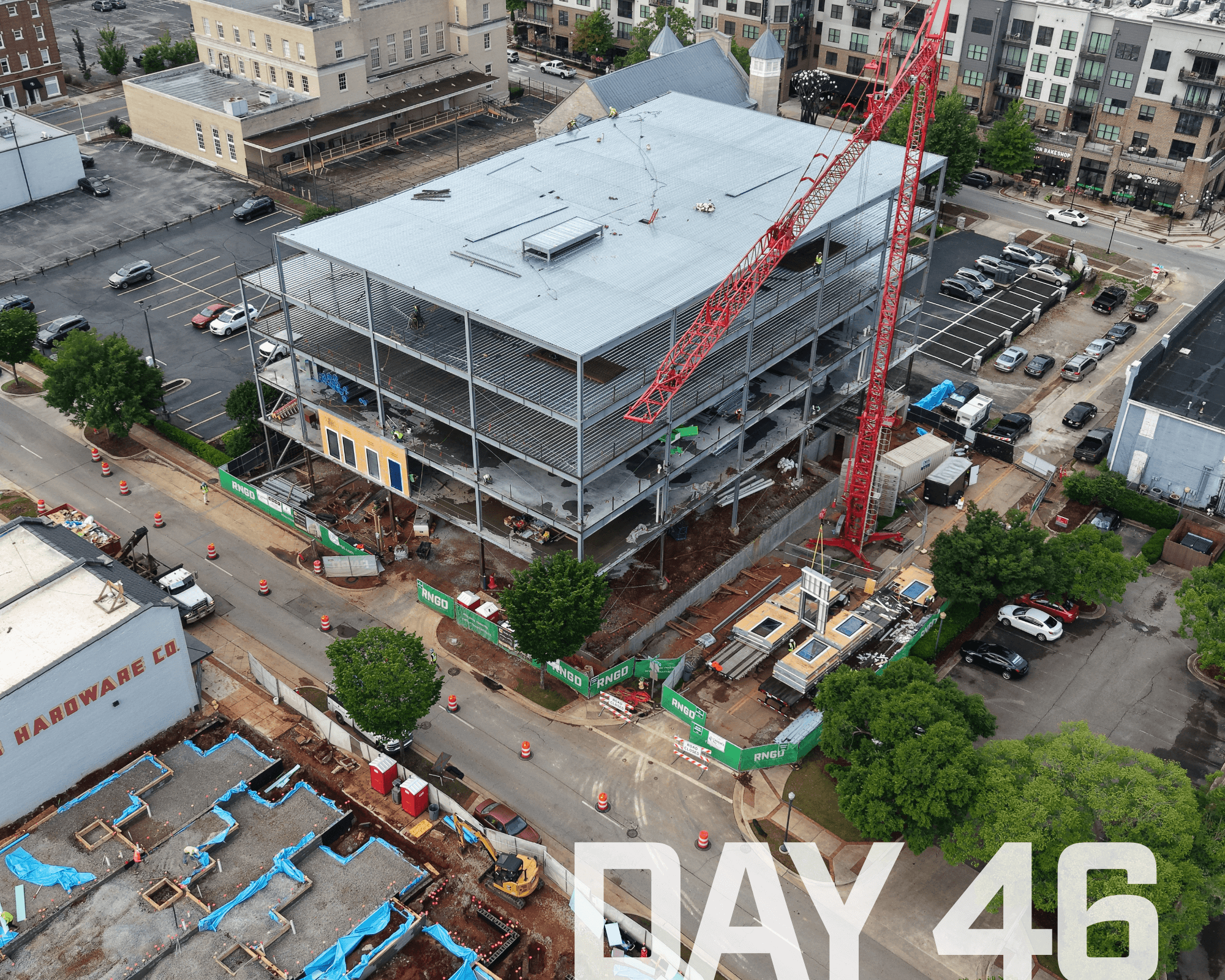

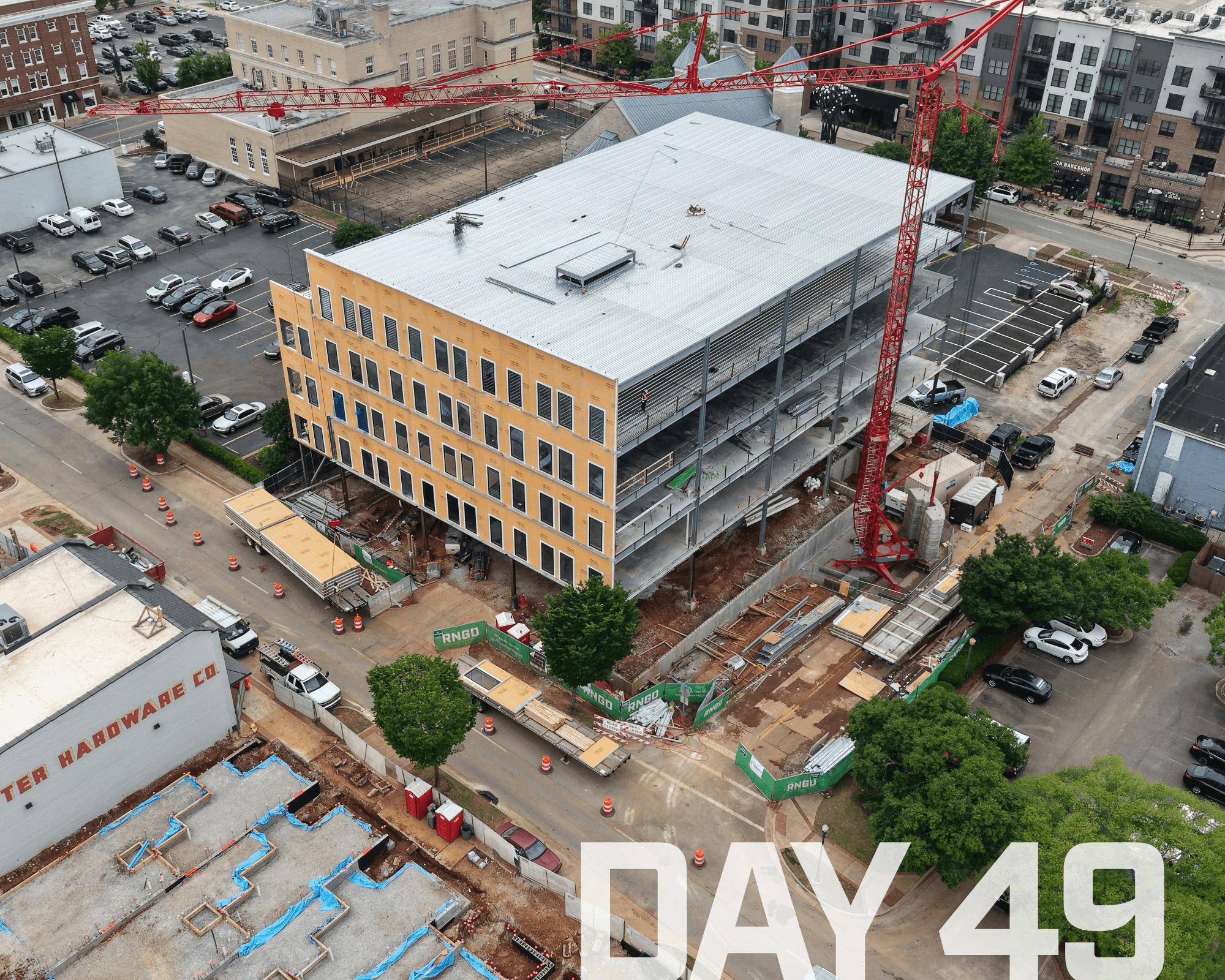

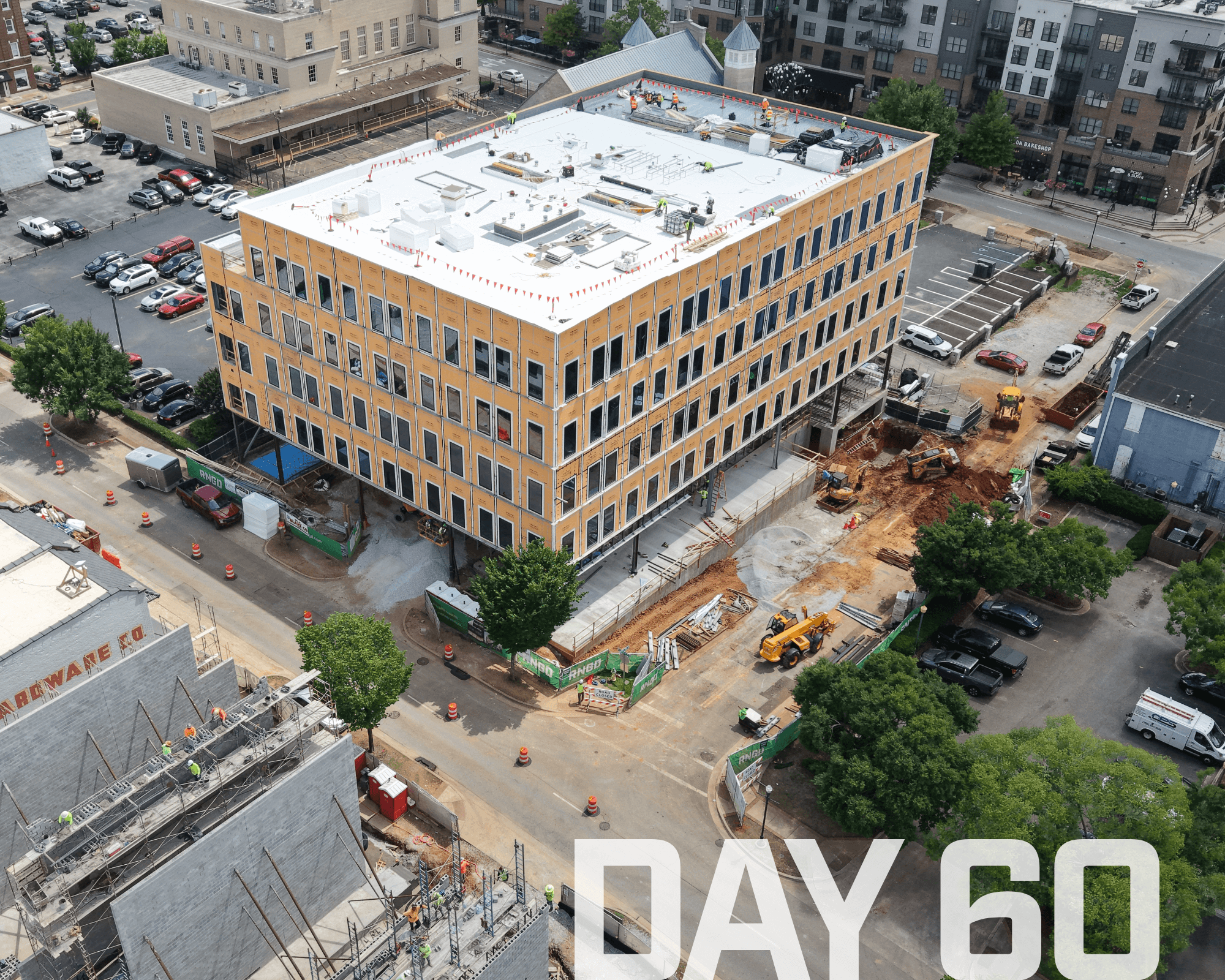

Ten Weeks That Changed the Schedule

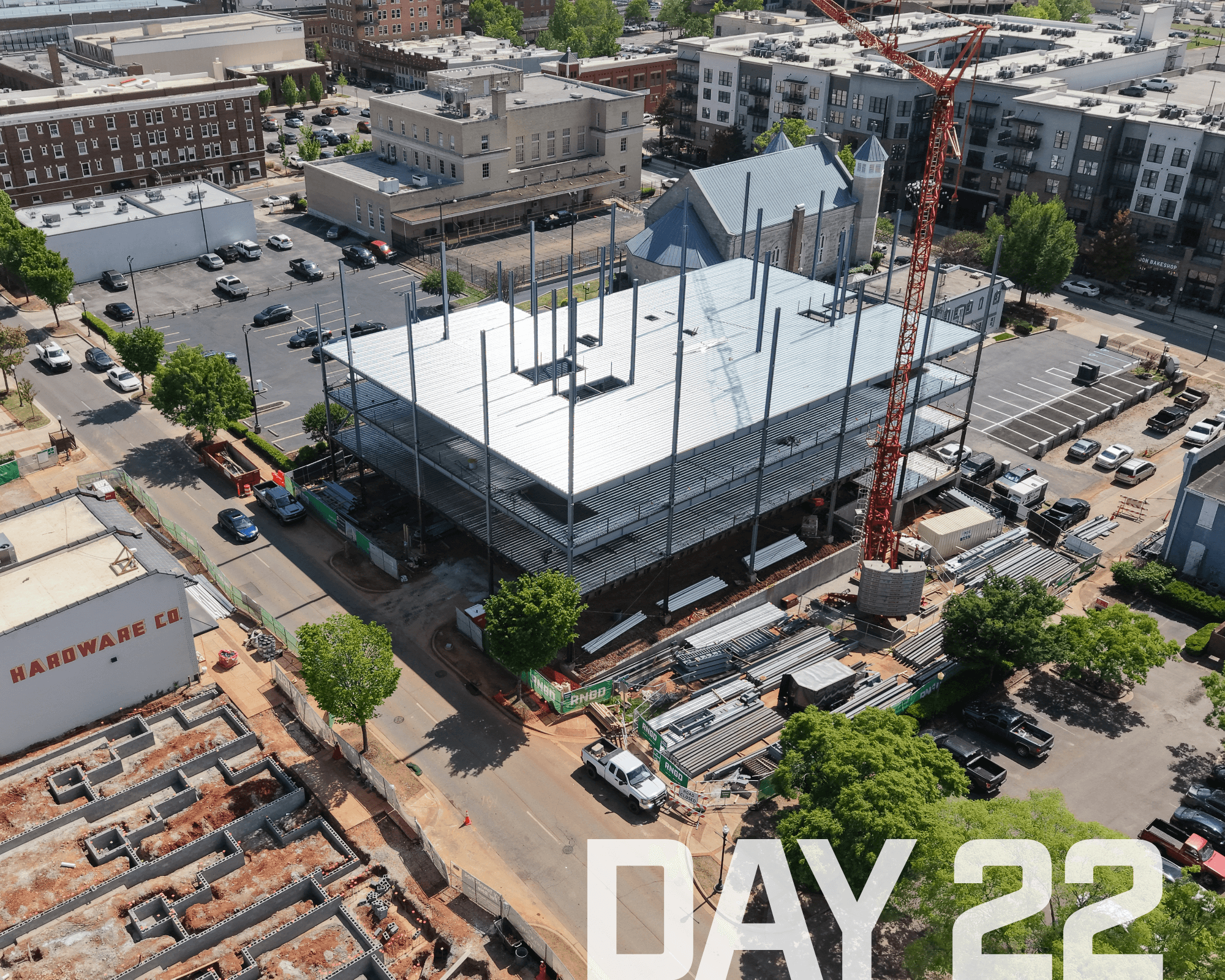

The payoff came fast. Over 400 tons of steel were erected in eight weeks. As steel wrapped up, prefabricated panels followed immediately behind. Two weeks later, the building was fully enclosed—ten weeks total from structure to weathertight.

That speed cut roughly four months from a traditional schedule, unlocking earlier interior work, reducing weather exposure, and delivering real value to the owner. More importantly, it proved what’s possible when planning, manufacturing, and field execution operate as one system.

The Lewter District Office now stands as downtown Huntsville’s premier Class A office destination—and as a clear demonstration of RNGD’s Renegade Delivery Method in action. Not as a concept, but as a repeatable way to deliver faster, higher-quality, more predictable results in the most demanding urban environments.