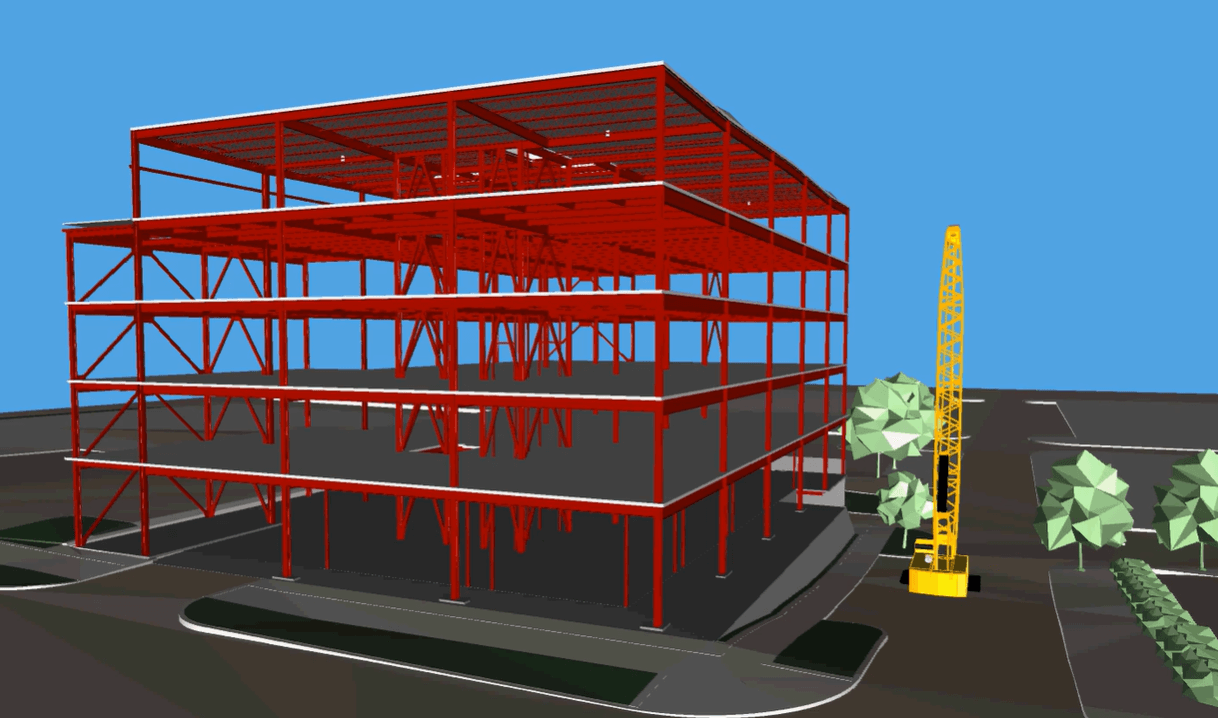

Lewter District Class A Office | Structural Steel

tons of steel

400 Tons

Location

Huntsville, AL

Owner

Emergent Properties

Industry

Steel

status

Completed in 2025

Overview

In the heart of downtown Huntsville, where space is tight and expectations are high, the Lewter District Class A Office set out to prove that urban construction doesn’t have to move slowly. The five-story mixed-use development demanded a structural system that could do more than carry loads. It needed to drive schedule certainty from the very beginning.

For RNGD’s steel team, the objective was clear: use steel not just as structure, but as a delivery tool. By integrating 400 tons of structural steel with a 30,000-square-foot prefabricated exterior panel system, the team set the foundation for an accelerated path to enclosure—one that would ultimately redefine what “fast” looks like on a dense urban jobsite.

Urban constraints demanded a different approach

The project site occupied an entire city block, leaving virtually no room for material staging or on-site storage. Surrounded by active streets and downtown traffic, steel deliveries had to be timed precisely, and erection sequences had to be executed with zero tolerance for missteps.

Limited access points, tight crane swings, and restricted working hours forced the team to rethink traditional erection methods. There was no opportunity for stockpiling steel or adjusting plans in the field. Every beam, column, and connection had to arrive ready for immediate installation, with erection sequences planned down to the smallest detail.

Planning and coordination turned constraints into control

To overcome these challenges, RNGD’s steel team leaned heavily into early coordination and disciplined planning. Detailed BIM modeling allowed the entire steel structure to be visualized in three dimensions, enabling clash detection and erection sequencing to be resolved well before steel ever arrived on site.

Custom connection details were developed to simplify installation within the tight footprint, reducing the need for rework or field modifications. Just-in-time deliveries were coordinated with crane operations, allowing steel to be lifted directly from truck to final position—minimizing congestion and maintaining a clean, controlled jobsite.

By self-performing steel fabrication and erection, RNGD’s Steel Team maintained full control over quality, sequencing, and safety, ensuring that every piece fit as intended and every lift advanced the schedule.

Precision execution delivered confidence and momentum

Through disciplined planning and self-perform execution, the steel structure rose efficiently despite the site’s tight constraints. The frame was erected safely and predictably, creating a stable platform that allowed subsequent scopes to mobilize without delay and keeping the project aligned with its aggressive schedule.

With the steel in place, the building was ready to receive 196 prefabricated, ready-to-install exterior panels, setting the stage for an accelerated path to dry-in. More than a structural success, the Lewter District Class A Office demonstrated how steel—when managed as an integrated, self-performed scope—can overcome urban constraints, drive certainty, and unlock momentum on complex projects.